This post was originally published on this site

Trouble and worrying are part of a vintage tube amp owner’s life. In this article, I will try to teach some basic troubleshooting for vintage Fender amps. It will only require a little practice, patience, and, most importantly, curiosity, which to me is the single most important skill in life—we can accomplish great things by reading, seeking advice, trying, failing, and not giving up. So, let’s start!

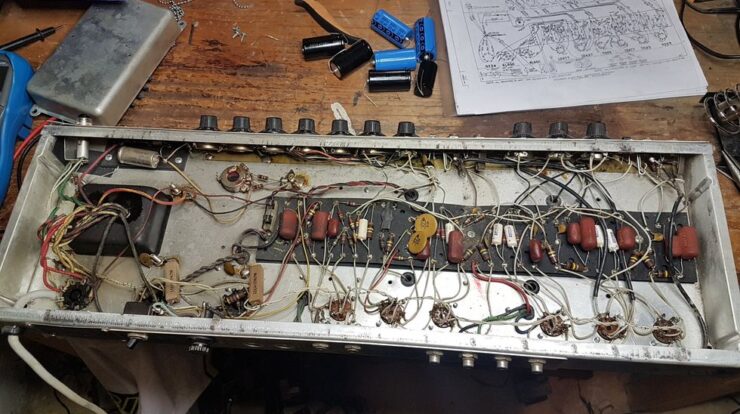

As usual, I will refer to the silver- and black-panel Fender amps, but everything is applicable to earlier amps as well. I will often refer to tubes: On a Deluxe Reverb, for example, the tubes are referred to from V1 to V9. Always consult your amplifier’s schematic to confirm these placements.

No Reverb

The reverb tank is the most delicate component of these amps. The springs, wires, and soldering joints are thin and weak, and the reverb cables and plugs are also easily damaged, as they are exposed on the backside of the chassis.

First, check the plugs on both the amp and reverb tank. Unplug and switch the input and output to see if the previous player made a mistake. Often, the plugs are damaged and not conducting current, or the inner wire or outer insulation are broken. I recommend replacing old cables with new, vintage-correct ones if you suspect the slightest cable or plug issue.

“Trouble and worrying are part of a vintage-tube-amp owner’s life.”

A bad V3 or V4 preamp tube may also cause reverb loss. If replacing tubes or reverb cables does not help, you should try hooking up another amp’s reverb tank to verify whether you have an amp or reverb tank issue. The reverb springs may also have jumped out of position and need to be re-attached. I recommend refreshing soldering joints here.

No Vibrato

First, the footswitch must be plugged in for the vibrato to work. If you don’t have one or suspect that it’s malfunctioning, you can either buy or make yourself an “always-on” phono plug that is shorted internally with solder. A bad vibrato-driver tube may also cause vibrato loss, which is fixed easily by replacing the V5 with another 12AX7. If none of this helps, a tech should open the amp and inspect the vibrato tube circuitry, and/or replace the opto-oscillator component.

Blown Fuse

Pull all the tubes before replacing a blown fuse. If the fuse blows repeatedly without any tubes installed, a tech should be involved for inspecting the filter caps/resistors, power transformer, and the high-wattage resistors on the power-tube socket pins.

If the pilot lamp light is on when all tubes are pulled out, start inserting tubes one by one from the V1 rectifier tube. Turn power/standby on. If the fuse blows, the rectifier tube is bad. Then, insert both power tubes and turn power/standby on. If the fuse blows, you need new power tubes, and possibly new screen and plate resistors. Continue this procedure for each of the preamp tubes until you identify corrupted tubes that draw too much current.

Weak Tone

Check speaker cable(s) and speaker terminals. I find it useful to connect to a second amp’s speakers to determine if it’s the speakers or an amp that is the problem. (Remember to turn off or set the amp in standby whenever speakers are disconnected.)

Then, verify that the tubes are working by following the previous “blown fuse” procedure. Look for loose power-tube sockets causing bad connections by gently pushing them around in the socket. If speakers, tubes, and sockets are working fine, a tech should further inspect the amp.

Distortion, Reduced Volume, or Weak Bass

When playing powerful 40-watt amps at low volume, it can be difficult to hear if only one tube is working. If one of the power tubes is malfunctioning, you will experience distortion and farty bass. Non-matching power tubes can also result in distortion and reduced clean headroom, which is detected by measuring with a bias meter.

Preamp tubes in wrong positions may also affect volume response and cause an amp to distort too early or too late. Check all tubes and replace them one by one with fresh ones as you listen for tone changes. Sometimes we prefer the wrong tubes because we like more distortion. (My tube strategy is to replace tubes only when they fail entirely. I don’t mind weaker power, rectifier, or phase-inverter tubes since these amps are more than loud enough.)

Rattling Noise

Loose screws and nuts can cause rattling noise and should be inspected and tightened regularly, including on the chassis, baffle board, tilt-back legs, speaker, handle, and anywhere else. If the baffle board is warped and worn so that the screws are not tight, I never hesitate to install a new, solid-pine baffle. This usually improves tone and robustness compared to old, warped MDF baffles