By Mitch Colby

Numerous terms related to guitar amp construction, features, and history are commonly misunderstood and misused. In fact, there are so many that it will take more than one Circuit column to cover just the ones that are most important to amp collectors. Let’s start with the following four:

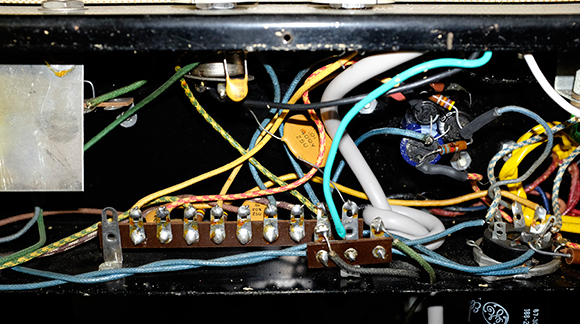

Point-to-point wiring: True point-to-point wiring (sometimes abbreviated “P2P”) uses rails, which are also known as terminal lug strips, without any circuit board. As a result, the electronic components are basically mounted in air. While this may be good for tone, amps that are built using true point-to-point wiring can be difficult to work on and often become a “rat’s nest” of wiring. Most vintage amps made by Valco (which includes the brands Gretsch, Montgomery Ward/Airline, National, Oahu, Sears/Silvertone, Supro, and more) were constructed this way through the mid Sixities, and some of the larger vintage Silvertone amps have wiring that is particularly messy. More recently, Matchless amps (made by noted Valco amp aficionado Mark Sampson) were wired this way.

Hand-wired: Amps with point-to-point construction are usually hand-wired as well, but the term “hand-wired” can apply to a significantly wider range of construction techniques. Totally hand-wired amps could have components mounted above phenolic or epoxy-glass boards (or wax-impregnated fiberboards) either using strip terminals (Vox), turrets (Marshall, Hiwatt), or eyelets (Fender). Most, but not all, modern “boutique” amps are wired this way. These amps are the easiest to maintain and repair as the components are easy to access for service or replacement.

However, some amps that have printed circuit boards may also be partially hand-wired. Usually this means that their pots, switches, tube sockets, and jacks are hand-wired and mounted securely directly to the chassis. This method is generally more robust and reliable than having the pots and sockets mounted directly to the circuit board for a number of reasons. Many acclaimed boutique amps use printed circuit boards (not that there is anything wrong with that) to facilitate construction and keep costs lower.

“British watts” vs. “American watts”: These terms aren’t as prevalent as they were years ago, particularly during the Seventies. The difference between the two even became the basis for an ad campaign about 35 years ago, when Rose Morris (the worldwide Marshall distributor) and Unicord (the U.S. Marshall distributor) put out advertisements that said something like “Marshall amps are louder because we use British watts, which are louder than American watts.” The terms came about because in England the people in charge of standards chose RMS (root mean square) watts as the way to measure power. Meanwhile, during the same time the U.S. used several different ways to measure power, including RMS, peak power, music power, and others.

Many companies would rate their amps using higher peak power standards, even though the amps actually put out less power than competing amps with a lower RMS power rating. One old U.K. Goodmans speaker I came across had two ratings printed on it: one in British watts and the other in American watts where the American rating was twice the British rating. The real reason that Marshalls were louder is that in the early days many of the amps that were rated at 100 watts actually delivered 100 watts without clipping. When fully driven into overdrive or distortion they could easily put out 150 or more watts, so naturally they sound louder than a distorted amp with peak power of 100 watts.

Plexi: The Marshall “plexi” era dates from around 1965 through the end of 1969, not including reissues. What distinguishes “plexi” Marshalls from others is the material that the front and back panels are made from. The “plexi” panel is a plastic called Perspex, the trade name for an acrylic material also known by the trade names Acrylite, Lucite, and Plexiglas. “Plexi” does not mean see-through, but rather it is a description for a Perspex panel that is painted gold and has black lettering. Marshall amps built before the “plexi” models had either white panels or lettering that was screened directly on the aluminum chassis. There are some JTM45s and JTM45/100 (the first production 100-watt heads) amps that have “plexi” front panels and cream-colored back panels. The term is most commonly misused as a description for hand-wired Marshall amps from 1969 through 1972 that actually had metal panels made of aluminum. While these are very cool amps, they are not “plexi”!

Mitch Colby helped develop many Marshall and Vox amp designs and is the founder of Colby Amplification.